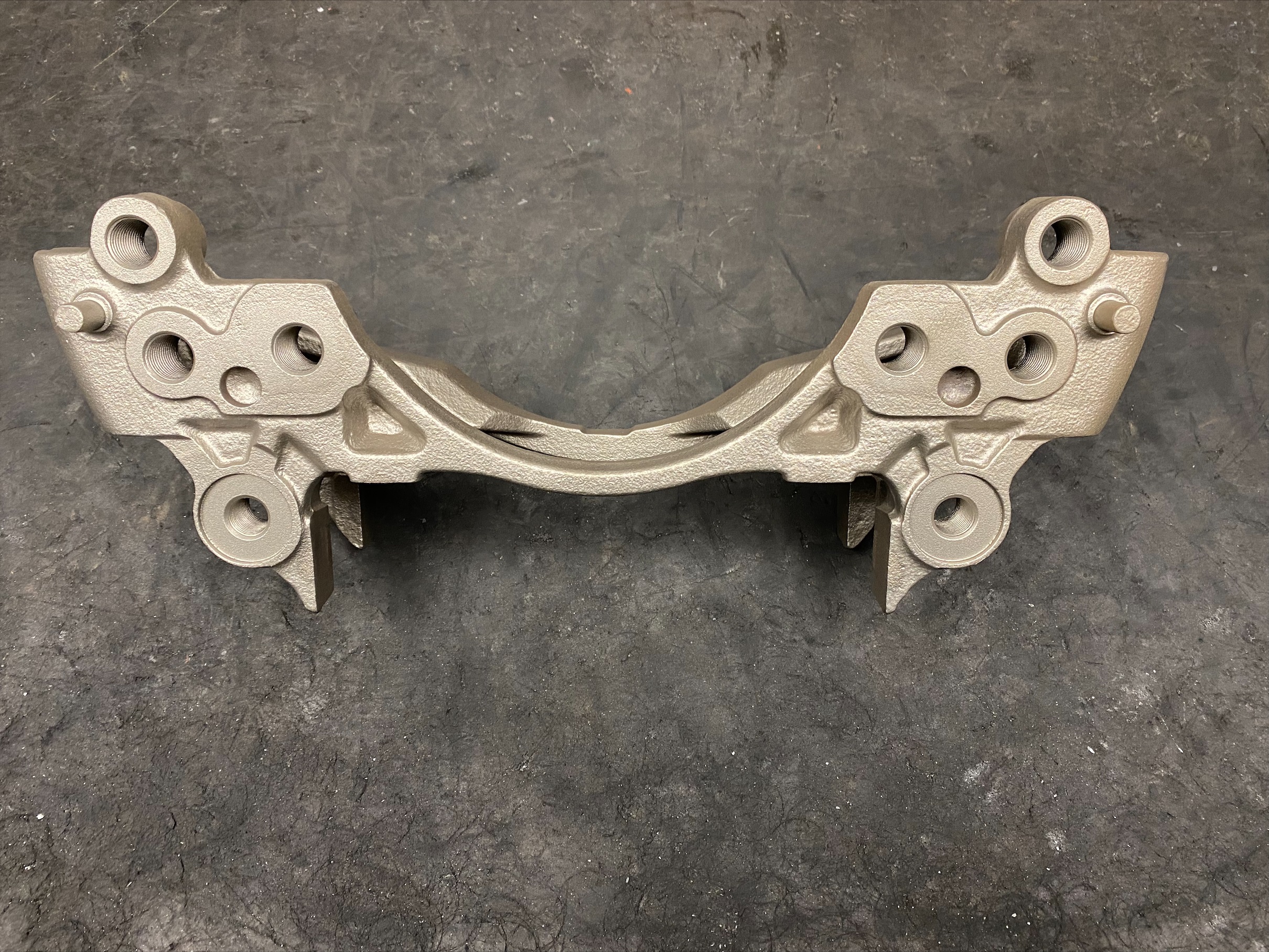

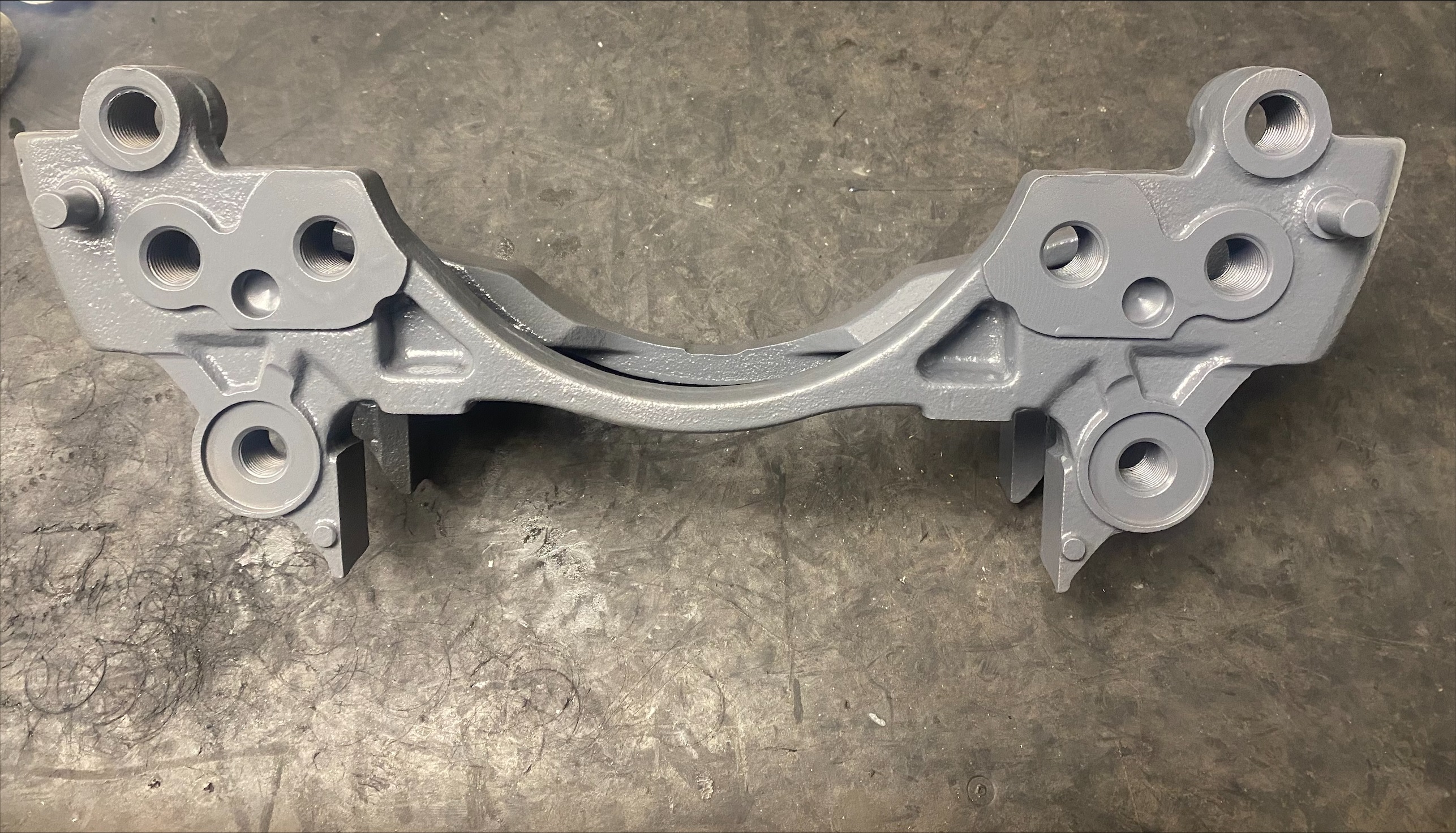

Caliper Refurbishment Step 1

It is a commonly known fact the remanufacture/recycling process of commercial brake calipers is environmentally green, so the whole process from start to finish is designed specifically to reduce waste and recycle as efficiently as possible.

Commercial Brake Tech’s brake caliper refurbishment process starts with a full unit strip down; separating the consumable parts, consisting of seals, bolts, bushes, and bearings. These items are then disposed of, and the metal items are sent for recycling. Analysis from the brake caliper strip down process is then officially documented and describes in detail why the unit has failed. The brake caliper carcass is then put through the cleaning processes before drying and checked for any defects and residual dirt.